References

Akrich, M., Callon, M., Latour, B., & Monaghan, A. (2002). The Key To Success in Innovation Part I: The Art of Interessement. International Journal of Innovation Management, 6(2), 187–206. https://doi.org/10.1142/s1363919602000550

Connor, R., & UNESCO World Water Assessment Programme. (2015). The United Nations World Water Development Report 2015: Water for a Sustainable World.

Boehm, H.P., Setton, R., & Stumpp, E. 1986. Nomenclature and Terminology of Graphite Intercalation Compounds. Carbon, 24, 241–245.

Daston, L., & Galison, P. (2010). Objectivity. Brooklyn, New York: Zone Books.

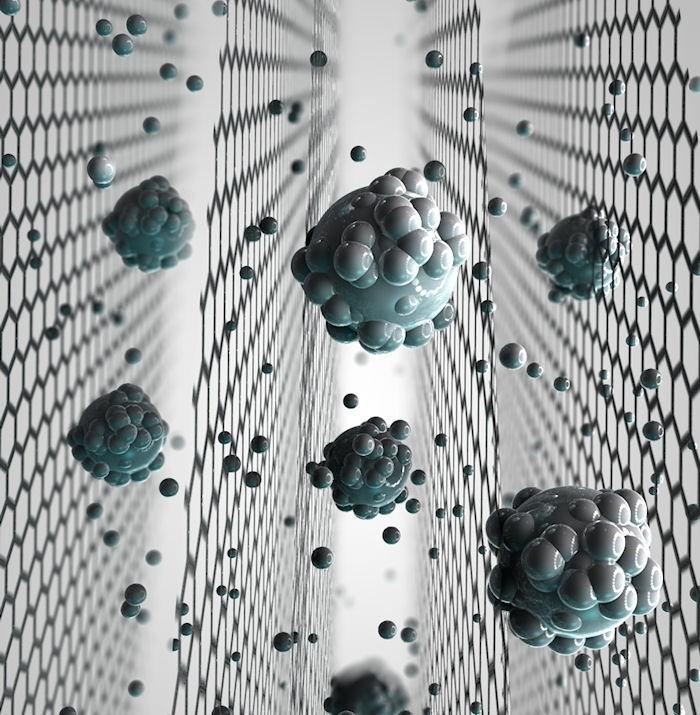

De Ridder-Vignone, K. D., & Lynch, M. (2012). Images and Imaginations: An Exploration of Nanotechnology Image Galleries. Leonardo, 45(5), 447–454. https://doi.org/10.1162/LEON_a_00442

Deleuze, G., Boundas, C. V., Lester, M., & Stivale, C. J. (2015). Logic of Sense. London: Bloomsbury.

Förster, K., 2022. Triangular Stories: Cement as Cheap Commodity, Critical Building Material, and a Seemingly Harmless Climate Killer. In A. Helle, A. Helle, & B. Lenherr (Eds.), Beyond Concrete: Strategies for a Post-Fossil Baukultur (pp. 35–65). Zurich: Triest Verlag.

Forty, A. (2012). Concrete and Culture: A Material History. London: Reaktion Books.

Geim, A. (2010). Nobel Lecture. The Nobel Prize. https://www.nobelprize.org/prizes/physics/2010/geim/lecture/

Hessenbruch, A. (2004). Nanotechnology and the Negotiation of Novelty. In Davis Baird & & J. Schummer (Eds.), Discovering the Nanoscale (pp. 135–144). Amsterdam: IOS Press.

Latour, B. (1987). Science in Action. Cambridge, Massachusetts: Harvard University Press.

Latour, B., & Woolgar, S. (1986). Laboratory Life: The Construction of Scientific Facts (2nd ed.). Princeton: Princeton University Press.

Minuchin, L. (2013). Material Politics: Concrete Imaginations and the Architectural Definition of Urban Life in Le Corbusier’s Master Plan for Buenos Aires. International Journal of Urban and Regional Research, 37, 238–58. https://doi.org/DOI:10.1111/j.1468-2427.2012.01203.x

Mol, A. (2002). The Body Multiple: Ontology in Medical Practice. Durham: Duke University Press.

Nobel Prize. (2010). Press Release: The Nobel Prize in Physics 2010. Retrieved January 3, 2022, from https://www.nobelprize.org/prizes/physics/2010/press-release/

Novoselov, K.S. (2011). Nobel Lecture: Graphene: Materials in the Flatland. Reviews of Modern Physics, 83(3), 837–849. Available at: https://doi.org/10.1103/RevModPhys.83.837.

Novoselov, K. S., Geim, A. K., Morozov, S. V., Jiang, D., Zhang, Y., Dubonos, S. V., & Firsov, A. A. (2004). Electric Field Effect in Atomically Thin Carbon Films. Science, 306(5696), 666–669. https://doi.org/10.1126/science.1102896

Novoselov, K. S., & Yaneva, A. (2020). The New Architecture of Science: Learning from Graphene. Singapore: World Scientific.

Nowotny, H., & Felt, U. (1997). After the Breakthrough: The Emergence of High-Temperature Superconductivity as a Research Field. Cambridge, UK: Cambridge University Press.

Robinson, B. (2017). Graphene Sieve Turns Seawater into Drinking Water. University of Manchester website. Retrieved from: https://www.manchester.ac.uk/discover/news/graphene-sieve-turns-seawater-into-drinking-water/

University of Manchester. (2021a). GEIC Hosts First Exterior Pour of Graphene-enhanced Concretene. University of Manchester website. Retrieved from: https://www.manchester.ac.uk/discover/news/geic-hosts-first-exterior-pour-of-graphene-enhanced-concretene/

University of Manchester. (2021b). Greener and Cheaper Graphene@Manchester Solves Concretes Big Problem. University of Manchester website. Retrieved from: https://www.manchester.ac.uk/discover/news/greener-and-cheaper-graphenemanchester-solves-concretes-big-problem/

Schofield, J. (2019). Manchester’s ‘Little Brasilia’ under Threat as Development Looms. Retrieved from https://confidentials.com/manchester/manchesters-little-brasilia-under-threat-from-id-manchester-university-development

Shamsaei, E. et al. (2018) Graphene-based Nanosheets for Stronger and More Durable Concrete: A Review. Construction and Building Materials, 183, pp. 642–660. Available at: https://doi.org/10.1016/j.conbuildmat.2018.06.201.

Stroll, A. (1988). Surfaces. Minneapolis: University of Minnesota Press.